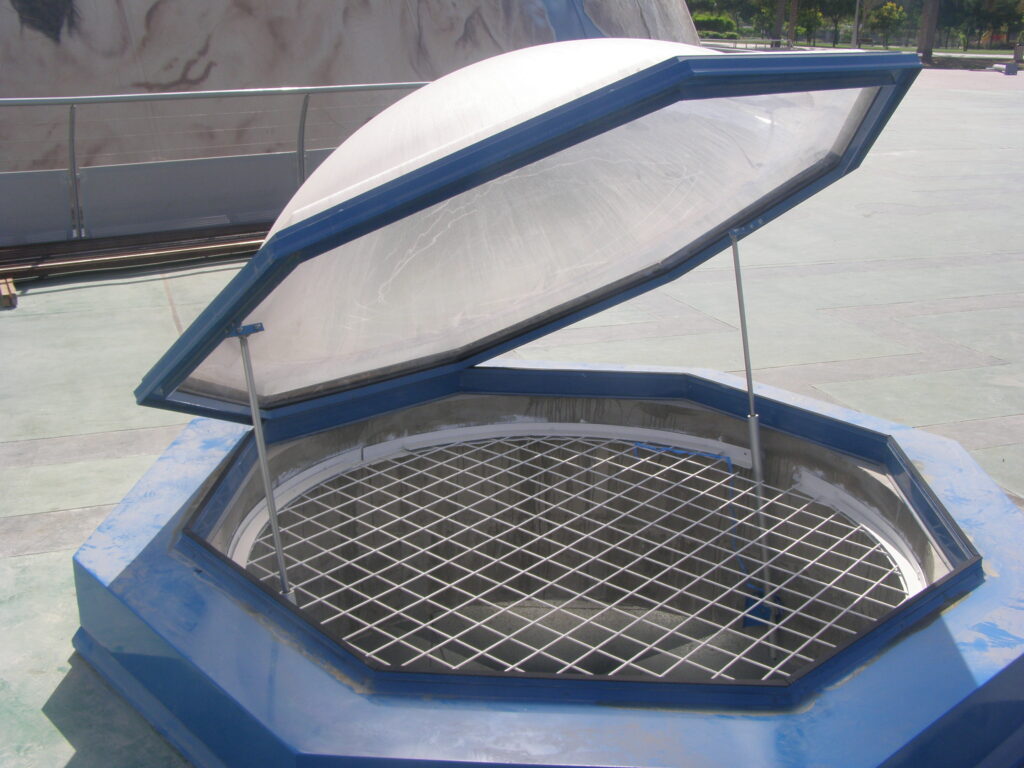

Al Mamary Polycarbonate Thermoforming Skylights System

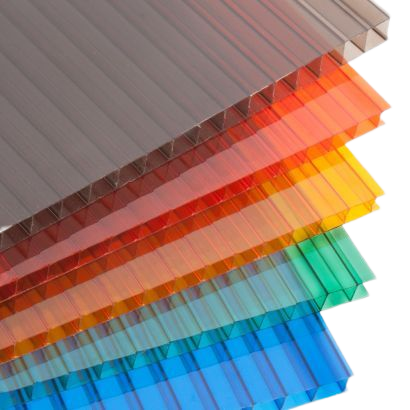

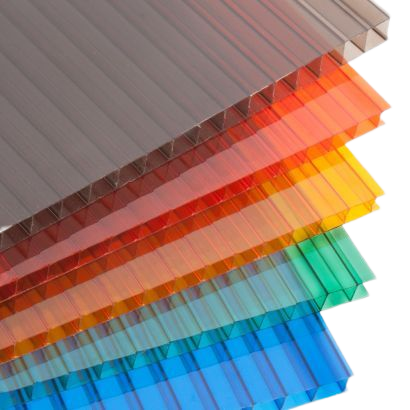

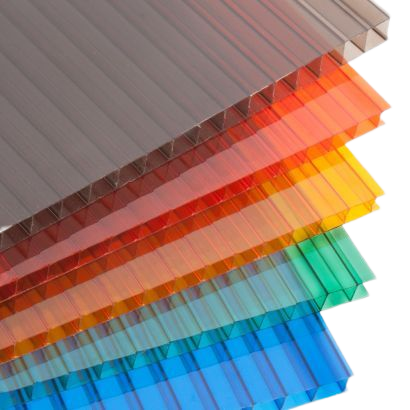

Al Mamary Sky domes is made from polycarbonate solid UV sheets which achieve many advantages compared to other materials like:

- Up to 250 times more impact resistant than glass

-

Light transmission value of up to 90 %, depending on the color and thickness of the sheets

- Absorb dangerous UV radiation

-

Can be used at temperatures between – 100 °C up to +115 °C.

-

Fire performance according to EN 13501-1 is B-s1-d0 or B-s2-d0, depending on thickness and color

- Reduce sound levels depending on sheet thickness

- Designed against the harsh weathering of GCC countries

-

Up to 10 years of limited warranty against yellowing

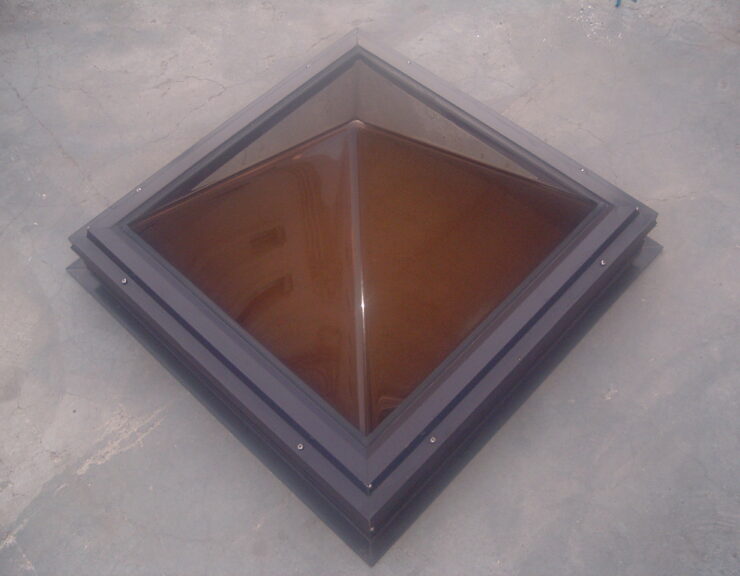

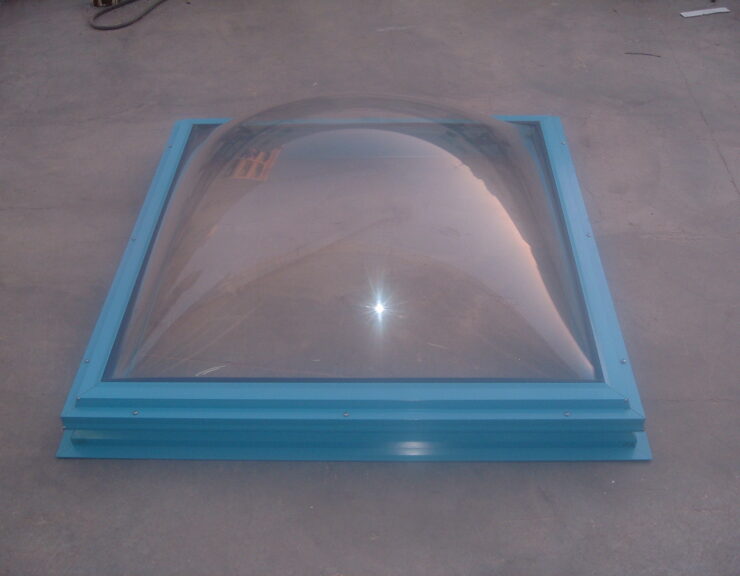

Thermoforming Skylights Design

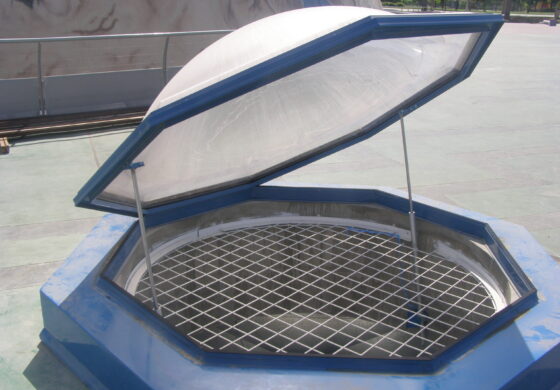

The best cost-effective choice for the skylight with a high level of safety and security is Al Mamary Polycarbonate Thermoforming System, providing the same insulating quality as the glass skylight and is much stronger as well.

Al Mamary Polycarbonate Thermoforming Skylights System's advantage is variability in sizes with a maximum unit size of 2 m x 2 m, just choose your size, and we will do the die for it.

For better thermal insulation, we can do single, double, or triple-layer glazing, as you can choose Dome or Pyramid shape.

For any span larger than 2 meters, this system can be used as a multi units of domes or pyramids by using special extruded aluminium profile gutter and chairs.

The advantages of using thermoformed skylights

Thermoformed skylights offer several advantages, including enhanced energy efficiency and durability. Here are the key benefits of using thermoformed skylights:

Thermoformed skylights are designed with energy efficiency in mind. They are typically made from advanced materials that provide excellent insulation properties, helping to reduce heat transfer and minimize energy loss. These skylights can contribute to energy savings by allowing natural light to enter the space, reducing the need for artificial lighting during the day.

Thermoformed skylights are engineered to optimize the transmission of natural light into the interior space. The design and materials used allow for increased light diffusion, minimizing glare and providing a more uniform distribution of light throughout the area. This not only enhances the visual comfort of occupants but also reduces the reliance on electric lighting during daylight hours.

Thermoformed skylights are known for their durability and ability to withstand various weather conditions. They are often manufactured from robust materials that are impact-resistant, UV-stabilized, and weatherproof. These skylights can endure exposure to harsh elements such as extreme temperatures, moisture, and UV radiation without deteriorating or losing their functionality.

Thermoformed skylights offer design flexibility, allowing architects and designers to create unique and customized skylight solutions. They can be molded and shaped into various forms, including domes, pyramids, and other geometric configurations, to match the architectural aesthetics and requirements of the project. This versatility enables architects to integrate skylights seamlessly into the building design.

Thermoformed skylights are typically low maintenance compared to other types of skylights. The materials used in their construction often have self-cleaning properties, reducing the need for frequent cleaning. Additionally, their durability minimizes the risk of damage and the associated maintenance or replacement costs over time.

Thermoformed skylights can be designed with built-in UV protection. These skylights incorporate special additives or coatings that block harmful UV rays, protecting the interior space from excessive solar heat gain and preventing fading or damage to furnishings, flooring, and other materials.

Overall, thermoformed skylights provide excellent energy efficiency, durability, and design flexibility. They are a reliable choice for bringing natural light into a space while enhancing thermal performance and minimizing maintenance requirements. Their combination of aesthetics and functional benefits makes them a popular choice for architects and building owners looking to optimize energy use and create visually appealing interiors.

The types of materials used in thermoforming skylights

Thermoformed skylights can be constructed using various materials, with acrylic and polycarbonate being commonly used options. Here’s a breakdown of these materials and their characteristics:

Acrylic Sheets

Acrylic sheets, also known as polymethyl methacrylate (PMMA), is a lightweight and transparent thermoplastic material widely used in thermoformed skylights. It offers several advantages:

Acrylic provides excellent optical clarity, allowing for high light transmission and a clear view of the sky. It offers exceptional light diffusion, reducing glare and providing a more uniform distribution of light.

Acrylic is highly durable and resistant to impact, making it less prone to breakage compared to glass. It has good resistance to weathering, UV radiation, and discoloration over time.

Acrylic has good insulation properties, contributing to energy efficiency by reducing heat transfer and minimizing energy loss.

Acrylic can be easily thermoformed into various shapes and sizes, offering design flexibility for architects and designers. It can be molded into domes, pyramids, and other custom forms to meet specific architectural requirements.

Polycarbonate Sheets

Polycarbonate sheets are another popular material used in thermoformed skylights due to its unique properties:

Polycarbonate is highly impact-resistant, making it a safe choice for areas prone to hail or falling debris. It can withstand significant forces without shattering or breaking.

Polycarbonate is lighter than glass or acrylic, making it easier to handle during installation. Its lightweight nature puts less strain on the skylight structure.

Polycarbonate can be manufactured with built-in UV protection. It has inherent resistance to UV radiation, which helps prevent yellowing, degradation, and loss of clarity over time.

Polycarbonate offers good thermal insulation properties, contributing to energy efficiency and helping to maintain a comfortable indoor environment.

Similar to acrylic, polycarbonate can be thermoformed into various shapes and configurations, providing design versatility to match specific architectural needs.

The types of materials used in thermoforming skylights

Thermoformed skylights can be constructed using various materials, with acrylic and polycarbonate being commonly used options. Here’s a breakdown of these materials and their characteristics:

Acrylic Sheets

Acrylic sheets, also known as polymethyl methacrylate (PMMA), is a lightweight and transparent thermoplastic material widely used in thermoformed skylights. It offers several advantages:

Acrylic provides excellent optical clarity, allowing for high light transmission and a clear view of the sky. It offers exceptional light diffusion, reducing glare and providing a more uniform distribution of light.

Acrylic is highly durable and resistant to impact, making it less prone to breakage compared to glass. It has good resistance to weathering, UV radiation, and discoloration over time.

Acrylic has good insulation properties, contributing to energy efficiency by reducing heat transfer and minimizing energy loss.

Acrylic can be easily thermoformed into various shapes and sizes, offering design flexibility for architects and designers. It can be molded into domes, pyramids, and other custom forms to meet specific architectural requirements.

Polycarbonate Sheets

Polycarbonate sheets are another popular material used in thermoformed skylights due to its unique properties:

Polycarbonate is highly impact-resistant, making it a safe choice for areas prone to hail or falling debris. It can withstand significant forces without shattering or breaking.

Polycarbonate is lighter than glass or acrylic, making it easier to handle during installation. Its lightweight nature puts less strain on the skylight structure.

Polycarbonate can be manufactured with built-in UV protection. It has inherent resistance to UV radiation, which helps prevent yellowing, degradation, and loss of clarity over time.

Polycarbonate offers good thermal insulation properties, contributing to energy efficiency and helping to maintain a comfortable indoor environment.

Similar to acrylic, polycarbonate can be thermoformed into various shapes and configurations, providing design versatility to match specific architectural needs.

It’s worth noting that both acrylic and polycarbonate have their own unique characteristics, and the choice between them depends on factors such as project requirements, aesthetic preferences, and budget considerations. Architects and designers should carefully evaluate these materials’ properties and consult with manufacturers or suppliers to determine the most suitable option for their thermoformed skylight application.

Thermoforming skylight customization options

Thermoformed skylights offer a range of customization options, allowing architects and designers to tailor the shape and size of the skylight to meet their specific project requirements. Here are some details about the customization options available for thermoformed skylights:

Shape

Thermoforming technology enables the creation of skylights in various shapes and forms, providing design flexibility. Some common shapes include:

- Domes: Dome-shaped skylights are popular for their aesthetic appeal and ability to maximize light transmission. They can be hemispherical, segmented, or custom-designed to suit the architectural style.

- Pyramids: Pyramid-shaped skylights offer a distinctive design element, often found in modern architecture. They can have square, rectangular, or multi-sided bases.

- Barrel Vaults: Barrel vault skylights have a gentle curved shape, resembling an elongated arch. They create a sense of openness and allow for natural light to spread evenly.

- Ridge Skylights: Ridge skylights follow the line of the roof ridge, providing an elongated and linear design element. They are commonly used in commercial or industrial buildings.

- Custom Shapes: Thermoforming allows for the creation of custom shapes and unique designs, providing endless possibilities for architectural creativity.

Size

Thermoformed skylights can be customized to various sizes to suit the specific requirements of the project. The size of the skylight is determined by factors such as the available space, desired light transmission, and architectural design. Skylights can range from small accent features to large expansive installations.

- Small Skylights: Small-sized skylights are suitable for spaces where a subtle introduction of natural light is desired, such as small rooms, corridors, or entryways.

- Medium-sized Skylights: Medium-sized skylights can illuminate larger areas and are commonly used in residential or commercial applications, providing ample natural light and visual appeal.

- Large Skylights: Large-sized skylights are ideal for spaces that require extensive daylighting and a striking architectural statement. They can create a dramatic effect, flooding the area with natural light.

Accessories

Thermoformed skylights can be complemented with various accessories to enhance functionality and aesthetics. These include:

- Ventilation Systems: Skylights can be integrated with motorized or manual ventilation systems, allowing for the controlled flow of fresh air.

- Shades and Blinds: Optional shading systems can be installed to control the amount of light entering the space and provide privacy when needed.

- Insulation and Energy Efficiency Features: Additional insulation layers or low-emissivity coatings can be applied to improve thermal performance and energy efficiency.

- Custom Finishes: Skylights can be finished with custom colors, patterns, or textures to match the interior or exterior design scheme.

It’s important to collaborate with experienced skylight manufacturers and suppliers who specialize in thermoforming to discuss specific customization options. They can provide valuable guidance on design possibilities, structural considerations, and the technical feasibility of customizing thermoformed skylights for your project.